-

Ammonium Polyphosphate Flame Retardant

-

Intumescent Flame Retardant

-

Halogen Free Flame Retardant

-

Fabric Flame Retardant

-

APP Ammonium Polyphosphate

-

Wood Flame Retardant

-

PP Flame Retardant

-

Additives For Adhesives And Sealants

-

Water Based Fire Retardant

-

Paper Fire Retardant

-

PU Flame Retardant

-

Halogen Free Fire Retardants

-

AP422 CROS484 Equal Type

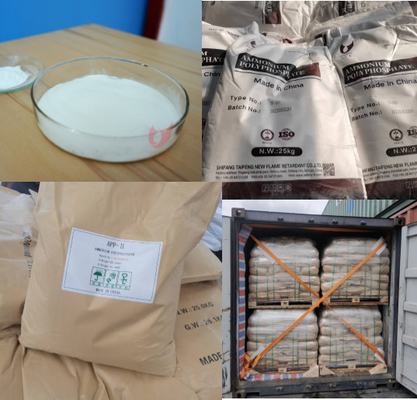

ISO9001 Fire Resistant Cloth APP Ammonium Polyphosphate

| Place of Origin | CHINA |

|---|---|

| Brand Name | TAIFENG |

| Certification | ISO9001, REACH, SGS |

| Model Number | TF-212 |

| Minimum Order Quantity | 100kg |

| Price | Negotiable |

| Packaging Details | 25kg/bag, 24mt/20'fcl without pallets, 20mt/20'fcl with pallets |

| Delivery Time | 10-15 days |

| Payment Terms | T/T, L/C, D/P, Western Union |

| Supply Ability | 200 ton per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Usage | Fireproof Fabric | Modified | Epoxy Resin Coated |

|---|---|---|---|

| Advantage | Hot Water Stain Resistance | Toxicity | Non-toxic |

| Viscosity | Low And Steady | TGA | More Than 270℃ |

| Highlight | Cloth APP Ammonium Polyphosphate,ISO9001 Ammonium Polyphosphate,ISO9001 Fire Resistant APP |

||

Fire Resistant Cloth Used APP Ammonium Polyphosphate With Hot Water Stain Resistance

Specification TF-212

Appearance White powder

P content (w/w) ≥30%

N content (w/w) ≥13%

Moisture (w/w) ≤0.5%

Average particle size ( D50) about 18µm

Bulk density 0.9-1.1 g/cm3

TGA, 99% ≥260℃

Solubility (25℃, g/100ml) ≤0.5

pH value (10% aq., at 25ºC) 5.5 – 7.5

Flame retardant fabrics have been processed with chemicals or fabrics are manufactured with a special fireproofing procedure in the manufacture of the fabrics. Fire retardant fabrics inhibit, suppress, or delay the ignite or spread of fire.

The flame retardant finishing is mainly on the surface treatment of the fabric in the process of textile finishing, that is, through adsorption deposition, chemical bonding, non-polar fan force bonding, and adhesion, the flame retardant is fixed on the fabric so as to achieve the flame retardant effect.

Advantages

1. No stain performance after hot water drops drying.

2. Good fluidity, not easy to cluster.

3. Good compatibility with acrylic emulsion.

4. Halogen-free and none heavy metal ions.

5. Low water solubility, migration resistance.

Application

Compared with 201, 212 works better in polyurethane emulsion, polyurethane glue, epoxy flame retardant and various resins.

Suitable for all types of flame-retardant textile coatings, especially for hot-water-stain-resistance acrylic emulsion coatings. Also suitable for other flame retardant fields that require higher water resistance and higher mechanical properties.

![]()

![]()

Packing

25kg/bag, 24mt/20’fcl without pallets, 20mt/20’fcl with pallets. Other packing as request.

Storage

In dry and cool place, keeping out of moisture and sunshine, shelf life two years.