-

Ammonium Polyphosphate Flame Retardant

-

Intumescent Flame Retardant

-

Halogen Free Flame Retardant

-

Fabric Flame Retardant

-

APP Ammonium Polyphosphate

-

Wood Flame Retardant

-

PP Flame Retardant

-

Additives For Adhesives And Sealants

-

Water Based Fire Retardant

-

Paper Fire Retardant

-

PU Flame Retardant

-

Halogen Free Fire Retardants

-

AP422 CROS484 Equal Type

Odorless APP HS Code 28353990 Paper Fire Retardant

| Place of Origin | CHINA |

|---|---|

| Brand Name | TAIFENG |

| Certification | ISO9001 / REACH |

| Model Number | TF-303 |

| Minimum Order Quantity | 100 kgs |

| Price | negotiation |

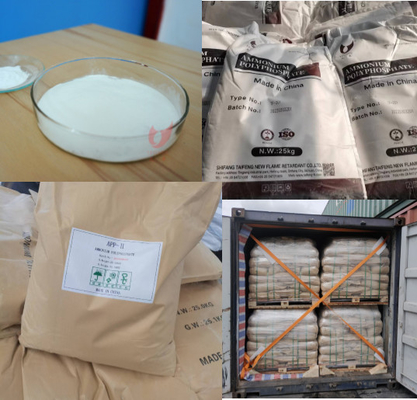

| Packaging Details | 25KG/Bag or 1MT/Super Bag, 24MT/20'FCL without pallets , 20MT/20'FCL with pallets |

| Delivery Time | 5-8days |

| Payment Terms | T/T, D/P, L/C, Western Union |

| Supply Ability | 200mt / month |

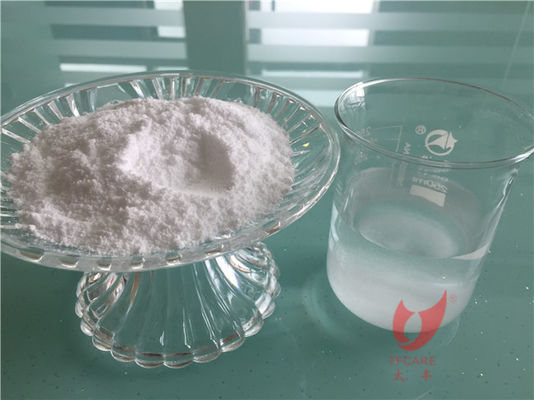

| Quality | Water Soluble Ammonium Polyphosphate High P Content | Appearance | White Powder |

|---|---|---|---|

| PH Value | 5.0-7.0 | Solubility | >150g/100ml Water |

| CAS No | 68333-79-9 | HS Code | 28353990 |

| Highlight | 28353990 Paper Fire Retardant,Odorless HS Code 28353990,Odorless Paper Fire Retardant |

||

High Phosphorus Content Water Soluble Paper Fire Retardant Ammonium Polyphosphate For Textile Wood Paper Flame Retardant

Generally, the paper used in daily life is mainly made of plant fibers, has no flame retardant effect, and easily burns under an open flame. Flame retardant additives are widely used in the paper industry. By using flame retardant treatment, paper will have certain flame retardant properties.

Application

1. Cover The Surface Of The Paper With Flame Retardant Solution

This method is also called the coating method, which uses the flame retardant aqueous solution or flame retardant dispersion liquid to brush and spray on the surface of the paper. This method can save the using amount of flame retardant and is easy to operate, but it can only achieve surface flame retardancy for thick paper, which is unfavorable for the overall flame retardancy of paper.

Usually in the coating method, flame retardants and adhesives are used together to improve the strength, abrasion resistance and waterproofness of the paper products.

2. Impregnating The Base Paper With Flame Retardant Aqueous Solution / Water Dispersion

Affected by the thickness of the paper, the dosage of flame retardant is usually 10-20g / m2. This method is carried out outside of the papermaking equipment, with short processing time and easy operation. It is suitable for all kinds of raw material paper, decorative paper, wallpaper, construction paper, etc.

The flame retardant impregnation treatment method of paper products is similar to that of wood. The flame retardant is generally configured as a 10% -20% aqueous solution, adding an appropriate amount of penetrant, and take out after a period of time, dried and smoothed to obtain a flame retardant paper product.

Most of the flame retardants used for impregnation are ammonium phosphate and water-soluble ammonium polyphosphate. In recent years, guanidine phosphate and sulfa are often used, but the treated paper is easy to absorb moisture and feels bad to touch.

| Specification | TF-303 |

| Appearance | White powder |

| pH value ( 10% water solution ) | 5.0-7.0 |

| Solubility (at 25ºC in 100ml water) | ≥150g |

| Water insoluble(25ºC) | ≤0.02% |

| P2O5 content (w/w) | ≥59.5% |

| N content (w/w) | ≥17.5% |

Packing

25kg/bag , 24mt/fcl without pallet, 20mt/fcl with pallet.

Storage

In dry and cool place, keeping out of moisture and sunshine, shelf life one year.

![]()

![]()