-

Ammonium Polyphosphate Flame Retardant

-

Intumescent Flame Retardant

-

Halogen Free Flame Retardant

-

Fabric Flame Retardant

-

APP Ammonium Polyphosphate

-

Wood Flame Retardant

-

PP Flame Retardant

-

Additives For Adhesives And Sealants

-

Water Based Fire Retardant

-

Paper Fire Retardant

-

PU Flame Retardant

-

Halogen Free Fire Retardants

-

AP422 CROS484 Equal Type

REACH High P-N Content Ammonium Polyphosphate Paper Fire Retardant

| Place of Origin | CHINA |

|---|---|

| Brand Name | TAIFENG |

| Certification | ISO9001 / REACH |

| Model Number | TF-302 |

| Minimum Order Quantity | 100 kgs |

| Price | negotiation |

| Packaging Details | 25KG/BAG , 17MT/20'FCL without pallets , 13MT/20'FCL with pallets |

| Delivery Time | 10 - 15days |

| Payment Terms | T/T, L/C, D/P, Western Union |

| Supply Ability | 200MT/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

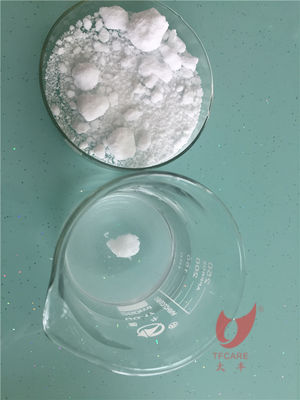

x| Quality | Water Soluble Ammonium Polyphosphate Low Arsenic | Appearance | White Crystalline Powder Or Lumps |

|---|---|---|---|

| Solubility | High , >80g/100ml Water | Arsenic | 2 Ppm Max |

| Storge | Cool And Dry Place | Eco-friendly | Halogen-free |

| Transportation | In Bags On Pallets | Effective Factors | P And N |

| Highlight | REACH Polyphosphate Paper Fire Retardant,High P-N content Paper Fire Retardant,REACH High P-N Ammonium Polyphosphate |

||

Low Arsenic Ammonium Polyphosphate Water Soluble Paper Flame Retardant More Eco-Friendly Low Heavy Metals

| Specification | TF-302 |

| P2O5 content (w/w) | ≥45% |

| Arsenic | 2ppm max |

| pH value ( 10% water solution ) | 6.5-8.5 |

| Solubility (at 25ºC in 100ml water) | ≥80g |

| Water insoluble(25ºC) | ≤0.02% |

Characteristics

1. High P-N content, proper ratio, good synergy and reasonable price

2. The pH value is neutral, safe and stable during production and use, good compatibility, and does not react with other flame retardant additives

3. Block solid, stable performance, easy to transport, storage and use

Application

1. Dipping - Immerse the substrate to be treated in the flame retardant, control the time according to the required flame retardant effect, dry it naturally, and dry it

2. Spray application - spray the flame retardant directly on the substrate to be treated, control the flow according to the flame retardant effect required, dry it naturally, and dry it

Packing

25kg plastic woven bag with PE liner, 17mt/20’fcl without pallets, 13mt/20’fcl with pallets.

Storage

in dry and cool place, keeping out of moisture and sunshine, shelf life one year.

![]()

![]()