-

Ammonium Polyphosphate Flame Retardant

-

Intumescent Flame Retardant

-

Halogen Free Flame Retardant

-

Fabric Flame Retardant

-

APP Ammonium Polyphosphate

-

Wood Flame Retardant

-

PP Flame Retardant

-

Additives For Adhesives And Sealants

-

Water Based Fire Retardant

-

Paper Fire Retardant

-

PU Flame Retardant

-

Halogen Free Fire Retardants

-

AP422 CROS484 Equal Type

Gray Odorless Ammonium Polyphosphate PU Flame Retardant

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Cas No | 68333-79-9 | Usage | Flame Retardant |

|---|---|---|---|

| Color | Grey Powder | Classification | Chemical Auxiliary Agent |

| Eco-friendly | Yes | Environmentally | Non-toxic, Low Smoke Production |

| Highlight | Ammonium Polyphosphate PU Flame Retardant,Odorless PU Flame Retardant,Gray Odorless Flame Retardant |

||

PU flame retardant APP flame retardant ammonium polyphosphate halogen-free OI 28%-32% class B1 or B2

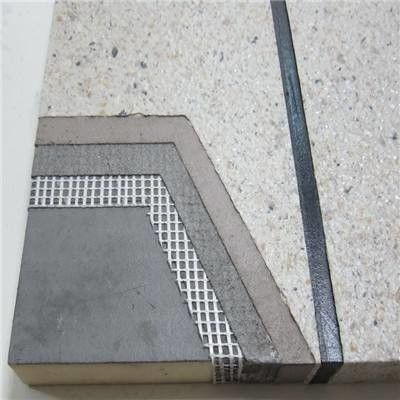

Rigid polyurethane thermal insulation board can be widely used in color steel sandwich board , central air conditioning , building wall materials , cold storage , cold storage , insulation box , chemical tank and other fields . But it is necessary to treated with fire retardant .

Ammonium polyphosphate can be used as flame retardant for rigid PU foam .

Ammonium polyphosphate TF-501 is used solely in flameproof treatment for rigid polyurethane foam. Total loading of 15% to achieve classification for burning behavior of building materials and products GB / T 8624-2012 B2 level .

Fire Retardancy:

| TF-501 | Sample | |||||

| 1 | 2 | 3 | 4 | 5 | 6 | |

| Average self-extinguish time(s) | 4 | 3 | 2 | 4 | 5 | 3 |

| Flame height(cm) | 15 | 17 | 13 | 12 | 13 | 15 |

| SDR | 83 | 74 | 73 | 88 | 81 | 93 |

| OI | 28 | 27 | 28 | 28 | 29 | 27 |

| Flammability | B2 | |||||

Mechanical Property:

| Formulation | TF-501 | Polyether | Rough MDI | Foamer | Foam stabilizer | Catalyzer |

| Addition(g) | 22 | 50 | 65 | 8 | 1 | 1 |

| Compression strength(10%)(MPa) | 0.15 - 0.25 | |||||

| Tensile strength(MPa) | 8 - 10 | |||||

| Foam density (Kg/m3) | 70 - 100 | |||||

Technical Data Sheet / Specification :

| Specification | TF-501 |

| Appearance | Gray powder |

| P2O5 content (w/w) | ≥47% |

| N content (w/w) | ≥8% |

| pH value (10% aqueous suspension, at 25ºC) | 6.5-7.5 |

| Moisture (w/w) | ≤0.5% |

Characteristics of TF-501:

1. Gray powder, expands when heated, efficient in smoke suppression.

2. Excellent water resistance, not easy to precipitate, high flame retardant efficiency.

3. Halogen-free and none heavy metal ions. pH value is neutral, safe and stable during production and use, good compatibleness, not to react with other flame retardant and auxiliary.

Application of RPUF:

The rigid polyurethane foam industry can be characterised in several, equally valid, ways. However, for the sake of this treatment, it is probably simplest to divide by application and subsequently by product/process. Accordingly, the first diagram describes the three main end-use sectors served by rigid polyurethane foams:

![]()

![]()

![]()